SANDBLASTING

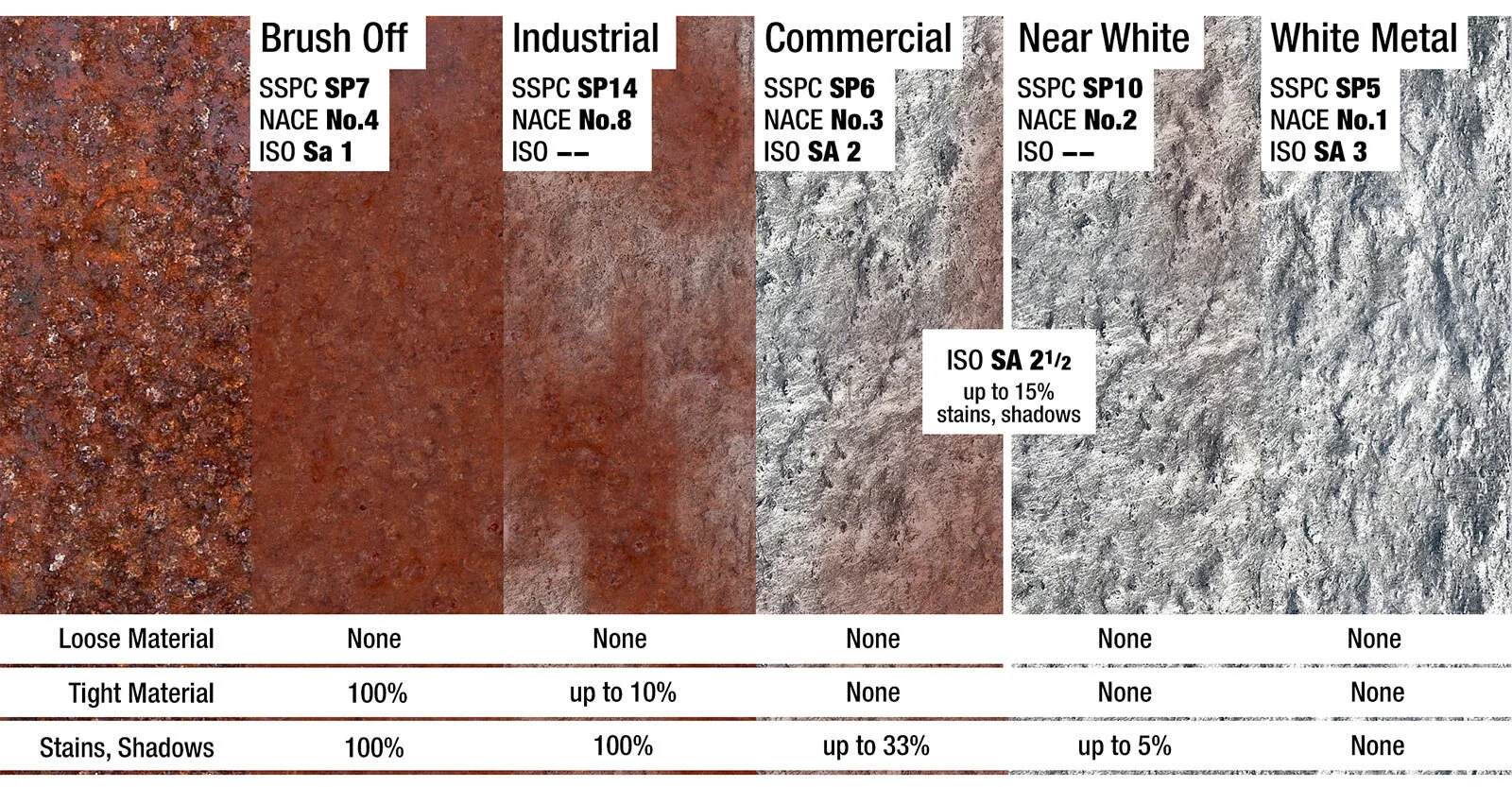

Pilot Sandblast & Coatings, Inc. provides a 50’x20’ sandblast room with the capability to perform SSPC-SP6, SSPC-SP10, and SSPC-SP5 level of sandblasting. We specialize in sandblasting steel, aluminum, and stainless steel. Our sandblast room can accommodate most large construction beams, frames, and assemblies. The process completely removes rust, dirt, oil, grease or any other contaminants. This provides the cleanest surface possible for future coatings. Sandblasting cleans the surfaces and allows a tooth-like surface that helps adhesion of all coatings applied after the sandblast process. We can also perform sandblasting as a matte textured finish on aluminum and stainless steel substrates.

https://www.graco.com/content/dam/graco/industry-solutions/abrasive-blasting/how-to/surface-prep-standards-comparison.jpg. A brief close-up image of sandblasted steel.

Powder coated unistrut

POWDER COATING

Powder coating is baked at 400 F or less in our 25’ or 15’ oven. We offer any powders that do not require a certifiable applicator. Our stock powders can be found in the Tiger Drylac Essentials Vol. 4 color catalog. We have catalogs and physical samples of colors available upon request. In addition, we can apply any powders available for purchase from any powder suppliers.

Known for its hard finish (technical term is “pencil hardness”), powder coating is one of the most durable coatings in the market of industrial coatings. It is applied electrostatically as a light/airy powder, then baked at the required temperature (normally 400 F) which melts and bonds to form its noted surface, see guard rail image below.

We have the ability to powder coat aluminum, steel, and stainless steel. We recommend that steel being assembled outdoors (exterior conditions) receive a zinc or epoxy primer prior to receiving the top coat to help prevent corrosion.

Most powder is as decorative as it is functional, while some powders are completely functional. We offer the ability to provide heavy duty epoxy powder coating of 3M #134 Fusion-Bonded Scotchkote Epoxy. The substrate is sandblasted to SSPC-SP10 standards, pre-baked, and then the coating is applied to allow the build up of a much thicker than normal coat of powder. This process is normally used for tank and pipe linings.

LIQUID COATINGS

Our facility also processes jobs which call for liquid coatings that are difficult to apply in the field. Our sandblast treatment, prior to the application of the liquid coatings, offers adhesion and a finish that cannot be replicated in the field.

We offer coatings like Tnemec 90-97 zinc-rich primer that has protective properties testing out at the same level as hot-dip galvanizing steel. This process is best for large wide-flange beams, columns, frames or steel stair case assemblies prior to them being constructed in the field.

We can also apply different types of epoxies in steel, stainless, and galvanized ductwork for chemical resistance. One of the top chemical resistant products we offer for the interior of ductwork is Tnemec 282 novolac epoxy.

Our preferred top coat for liquid processing is high solids polyurethane (Tnemec 750 UVX and 1075, or the high performance Fluoronar coating, Tnemec 1072). This type of coating is a two-part coating that hardens and feels like powder coating, although it is not actually the same pencil hardness. Our liquid coatings have the ability of being matched to any color and/or gloss level desired.

As powder coating and liquid paint applicators, we execute the jobs based on the customers’ needs and specifications. However, if we cannot complete or do not recommend the requested process for a job, we can usually provide the best option available to achieve the desired finish. We do not fabricate any metal in our facility.

For further inquiries and quotes, please do not hesitate to call or email us. We look forward to working with you!